Ansys Blog

February 1, 2019

5 Trends in the Aerospace Industry

Every January, I discuss aerospace industry trends with customers, thought leaders and engineers.

Based on these discussions, some of the biggest aerospace industry trends in 2019 will focus on improving:

- Propulsion.

- Autonomous systems.

- Additive manufactured parts.

- Maintenance, repair and operations (MRO).

Aircraft refueling might become a thing of the past if electric propulsion becomes a reality

These movements in the aerospace industry all combine into one last trend, the added complexity of flight systems.

The only way to safely address the complexity of flight systems, and meet market demands, is to use multiphysics simulation across the entire life cycle of the product — from pre-design to MRO operations. This is what Ansys’ Pervasive Engineering Simulation is all about.

1. Reduce Flight Costs and Emissions through Electric and Hybrid Engines

Aerospace thought leaders are highlighting the need to preserve the environment and follow regulations, while boosting the performance of aircraft engines.

In other words, aircraft engines need to output more power while consuming less fuel, producing less noise and releasing less emissions.

To achieve this goal, the aerospace industry is enhancing the efficiency of combustion engines, while also exploring electric and hybrid propulsion systems.

The aeroacoustics of these engines will also be a design focus. This is especially necessary as drones and urban air mobility (UAM) vehicles begin to fly over populated areas.

Electric and hybrid aircraft

engines will reduce costs

and emissions.

- Materials.

- Batteries.

- Inverters.

- Cables.

- Control electronics.

- Software.

Multiphysics simulations enable engineers to account for all of these variables when designing electric and hybrid aircraft engines. To learn more, check out ourElectric Machine Webinar Series.

2. Autonomous Flight Systems Will Be the Future of the Aerospace Industry

Autonomous flight systems are another trend in the aerospace industry.

Autonomy will take on many forms — from drones to space vehicles.

Any science fiction fan knows that autonomous flight systems are fundamental to the future of space travel.

Though humans have launched probes into space, they are vulnerable if they experience anything unexpected.

Autonomous drones are the future

of the aerospace industry.

If these probes wait for mission control, it would take hours or days to send and receive a response. By that time, the probe could be destroyed.

Back on our planet, companies are building the business case for local air transportation — the aforementioned UAM. These aircraft systems would connect nearby regional airports. The economics behind UAM only work by reducing the crew to a single pilot or an unmanned system.

Single pilot aircraft require a high degree of automation and a cockpit redesign. To perform this cockpit redesign, engineers can use:

- Ansys SCADEto optimize the embedded software.

- Ansys optical simulationsto ensure the pilot can read instruments in all weather conditions.

To develop fully autonomous aircraft, engineers will need to perform closed-loop simulations between the sensors, control software and intelligent algorithms. Virtual realities and multiphysics simulation will be the only ways to test these autonomous flight systems to react to all possible situations in a reasonable timeframe.

To learn more, read:Safe System Design and Autonomous Vehicle Software Development

3.MRO的新航空技术将依靠Sim卡ulated Data

The MRO market is steadily growing thanks to the increasing number of aircraft and their mounting complexity.

Currently, airline budgets are bogged down by surprise maintenance. By timing maintenance cycles to prevent malfunctions, engineers can minimize the expenses associated with grounding an aircraft.

This is why the current generation of aircraft can generate a lot more data than previous generations.

The future of MRO will rely on simulation.

This data are used by engineers to better understand, and predict, how systems are performing. Predictive maintenance is already bringing big savings to the industry.

However, these predictions are less effective at predicting the behavior of new technologies because they are based on historical data. The aviation industry cannot wait for 10 years of data to implement predictive maintenance tools for the next generation of flight systems. The solution is to use data from simulated failures to fill in the gap.

To learn more, read:The Need for Speedy Innovation in the MRO and Aviation Industries.

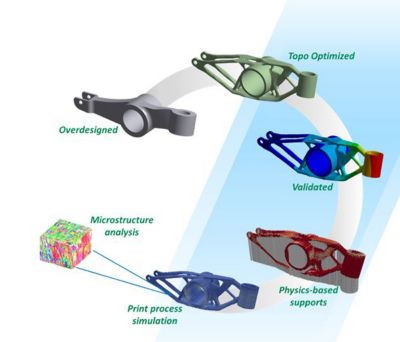

4. Additive Manufacturing Consolidates and Lightweights Aerospace Parts

Additive manufacturing is another trend that is flying through in the aerospace industry. In fact, additive manufacturing of metal parts is of particular interest to many engineers.

These engineers are starting to realize that additive manufacturing — coupled with topology optimization — offers more to the aerospace industry than lighter parts. They can also consolidate parts.

By consolidating parts, engineers will cut assembly costs and time. These fewer, lighter parts will also simplify maintenance and save on fuel.

Topology optimization and additive

manufacturing can lightweight and

consolidate aircraft parts.

Additive manufacturing also gives aerospace manufacturers the freedom to produce parts on-demand. This will make the supply chain more efficient.

However, the main problem with additive manufacturing — beyond certification — is that it requires a high level of expertise that is still hard to find.

The printing process must be designed in a way to avoid deformation and stresses, and to reduce the number of supports. Poorly optimized printing processes will lead to many scrapped parts, wasting precious time and money. Therefore, manually iterating the printing process isn’t a viable option.

In short, designing parts for additive manufacturing is not easy; simulation must be used to optimize the printing process. To learn more, read about theAnsys Additive Suite.

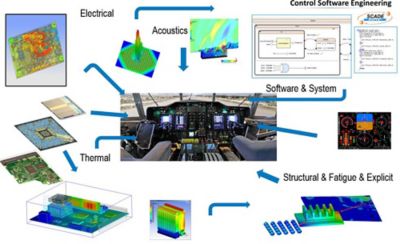

5. Growing Complexity in the Aerospace Industry Has a Multiphysics Simulation Solution

All of the previous trends have something in common — complexity. This complexity is associated with a lot of risks that could cost time and money.

Designing and optimizing aircraft is a multiphysics problem.

Multiphysics simulations have a significant role in tackling these complex challenges and minimizing their risk. In multiphysics simulations, the results from physics domains feed, and at times feedback, into each other. This means that engineers are better equipped at predicting how the aircraft systems will react in the real world.

However, the industry is strongly attached to its legacy systems, simulations and processes. Engineering teams still focus on single physics domains before passing results to another team. Aircraft are becoming too complex for this siloed approach.

Multiphysics is still a big mindset change that many companies are struggling with. However, its validity has been demonstrated by many startups in the space sector. Companies like Virgin Galactic and SpaceX have achieved incredible success in a few short years — threatening market leaders.

The complexities that are growing in the aerospace industry will not be solved by a series of single physics simulations. It’s time to accelerate development and test phases — the only possible answer is multiphysics simulation.

To learn how to tackle some of these trends with simulation, read:6 Simulation Technologies Aerospace Engineers Don’t Want to Miss in 2019.