ANSYS ADVANTAGE MAGAZINE

January 2021

Startup Beams Power to the IoT

By Roland Tallos, Chief Engineer, Nikola Labs, Columbus, U.S.A.

Nikola Labs' Vero system

Wirelessly powering devices may seem like a new idea, but its origins go back as far as 1899, when Nikola Tesla built and demonstrated the Tesla Experimental Station in Colorado Springs. His high-voltage, high-frequency experiments proved the concept of wireless power rather too dramatically: The artificial lightning generated millions of volts and caused sparks to jump between nearby pedestrians’ feet and the ground.

Today, research and engineering teams are working on much lower power systems to wirelessly recharge things like smartphones and Industrial Internet of Things (IIoT) sensors. Nikola Labs in Columbus, Ohio, is working on the industrial side of this challenge. A participant in theAnsys Startup Program, the company was founded in 2015 at Ohio State University to commercialize the ideas of Professor ChiChih Chen, which involve transfer of power through radio frequency (RF) electromagnetic waves transmitted between antennas. The company now has about 30 employees dedicated to providing an endto-end solution for remote machine condition monitoring. Machine health is measured using an ultra-low power receiver composed of a temperature sensor and an accelerometer. While the receivers currently operate in the field for long periods of time on a single battery charge, they could eventually benefit from the wireless power technology that Nikola Labs is developing.

But, like many startups, they had to design and demonstrate prototypes for many different potential clients with a wide range of applications before they hit on vibration sensor technology. And they are still looking for opportunities in other verticals, like smart buildings, to expand their business. One thing has been constant along the way:Ansys HFSS.

Wireless Power Exploratory Projects

Early on, a company approached Nikola Labs about using wireless power to replace the battery in a battery-assisted passive (BAP) near-field communication (NFC) tag to boost its read/write range. Instead of using batteries that required maintenance, they wanted to use energy harvested from a 2.4 GHz transmitter source that was part of the NFC reader to supply the bump in power needed to increase the read/write range. The company already had an antenna on top of a bottle cap and wanted Nikola to provide a wireless power solution in the small space around this antenna. That involved designing a “conformal” antenna that would fit around (conform to) the existing 13.56 MHz NFC antenna and accompanying NFC integrated circuit (IC), all in a diameter of about 1 inch. Nikola’s antenna design received 2.4 GHz RF power to supply their energy-harvesting system-in-package (SiP). The SiP then converted the RF power to DC power for the NFC IC, increasing the read/write range without using a battery.

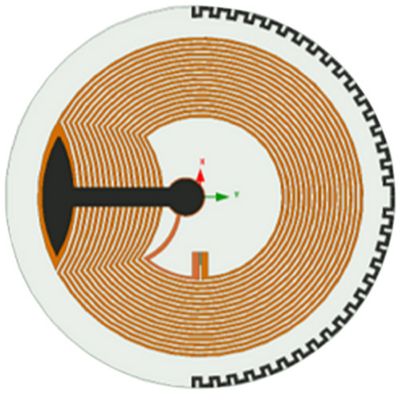

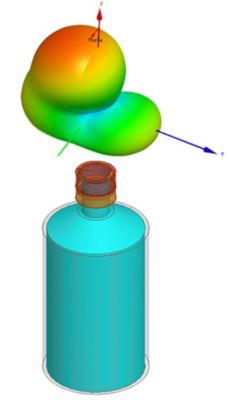

Using HFSS, Nikola Labs engineers first modeled basic antenna geometries around the NFC antenna, keeping everything planar at first to minimize initial simulation time. To fit into the small diameter available, they decided to use a meander dipole antenna, the shape of which “meanders” back and forth to fit a long antenna length into a small space. They took advantage of the parametric sweep feature of HFSS, studying a number of variables to gain an understanding of how the different values for the variables would affect the design. Nikola engineers were able to show that a horizontal dipole around the NFC antenna, which acted as a ground plane, could harvest enough energy to make this solution feasible. Then they began to add more details to the simulations, from the copper trace thicknesses on the board all the way up to the whole bottle filled with liquid. They eventually built a prototype and demonstrated that it worked, but for various reasons the client decided to go in another direction.

Another company wanted to use wireless charging technology to power a temperature and humidity sensor in an office space. The goal was a more efficient heating, ventilation and air conditioning (HVAC) system. They also wanted to include solar cells that would absorb some of the energy of office lights to capture a portion of that normally wasted power. The device had to be small to be integrated into the top of a cubicle wall or an office desk with the power source above it in the ceiling. Nikola Labs realized that they needed a split beam antenna pattern with hardware to control the angle of the two beams pretty tightly, and there did not seem to be enough space. So they used HFSS to figure out how to configure the size, shape and materials of the antenna system to guide the beam at the correct angle. This involved varying the size and type of substrates and the dielectric material using parametric sweeps. Again, the prototype was a success but the project did not go forward — a rather typical series of events for a startup looking for its niche.

HFSS model of the meandered dipole antenna around an NFC antenna

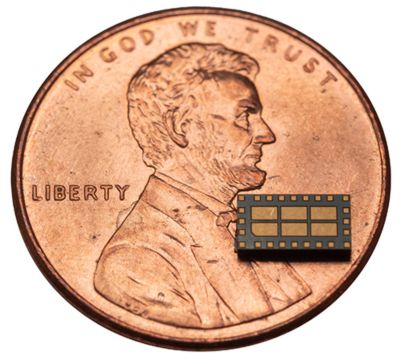

RF-to-DC system-in-package (penny included for scale)

Finally the Right Project

2017年,尼古拉实验室对designin接洽g a sensor consisting of a receiver with an accelerometer to monitor the condition of machines through vibrational analysis. Accelerometer data can be converted into vibration data, which experts can review to learn about the condition of a machine — like a motor housing or bearing housing, typical points of wear and tear in industrial settings. Existing sensors of this type have a short battery life, which requires continual maintenance for battery replacement. Nikola engineers are tackling the battery life problem in two ways. First, they focused on designing the receivers to be ultra-low power, extending the system life off a single battery charge. Then, they used HFSS to focus on the RF side to design antennas that they use to harvest RF power. The harvested RF power is then fed to their energy-harvesting system-in-package, which consists of an RF-to-DC rectifier circuit and a DC power management circuit together in a tiny package. On the transmission side, they simulated different transmitters to beam power to the receiver. In this way, Nikola engineers are working toward marrying the sensor with their wireless power technology to transfer data to the sensors and provide power wirelessly, extending the sensor life up to 10 years or so.

一个正在开发的系统有一个中心,which is a router that collects the data from the sensors and transmits wireless power to them. The sensors are mounted on the industrial equipment being monitored. Current wireless technology can harvest only 100 microwatts on average, so that has to be sufficient to power the system. The question becomes how often can you turn your sensor on, gather the data and send it out given the small amount of power that is being harvested? Striking a good balance is essential to optimizing sensor life. Currently, data is gathered from the sensors at least eight times a day. The distance between hub and sensor is ideally no more than about 5 meters, because that distance is the break-even point in terms of power harvested vs. power consumed. The system under development powers about six sensors per hub now, but that number could be higher if the power balance were optimized and system performance were increased.

Customers are always asking for smaller components, which is a strain on the hardware. With the power available for transmission being fixed, and no large gains to be made on the RF to DC side of the system. The biggest impact possible is on the performance of the harvester's antenna on the receiver side. To optimize this impact requires being able to rapidly simulate numerous types of antennas using different techniques and different designs. Being able to iterate quickly is a major advantage of HFSS. Nikola engineers use HFSS to quickly iterate and vet new ideas and new materials for antenna design. HFSS is also used on passive RF circuits, like power splitters, combiners and filters. As a final check, Nikola engineers import the printed circuit board (PCB) geometry into HFSS to run simulations to ensure that everything is behaving correctly before prototypes are made.

Machine Learning Optimization on the Horizon

By focusing on the vibration sensors for the last year and a half, Nikola Labs now has 40+ customers with 70+ facilities, with numbers on the rise. They currently monitor over 900 major pieces of industrial equipment and have collected more than 32 million readings to date.

Ultimately, Nikola engineers want to use the data they collect to develop machine learning techniques to further optimize the performance of the equipment. They are also looking for opportunities in other IoT verticals, like smart buildings. When they find them, HFSS will be in their toolkit to take on the toughest challenges.

The 3D radiation pattern of the dipole antenna when it is mounted on top of the bottle