ANSYS BLOG

January 3, 2023

What is Reynolds Number?

Have you ever looked at a flow in nature — at a waterfall, perhaps — and wondered why it flows smoothly? Or chaotically? Or both? The answer lies in the relative magnitude of different forces in the flow, which can be represented by calculating the Reynolds number — an important dimensionless parameter used in fluid mechanics to help predict the behavior of fluids. The Reynolds number is often misrepresented, however, which can lead to inaccurate predictions. To understand the Reynolds number and its importance, it is necessary first to understand what it is and how to calculate it.

Reynolds Number Equation with Flow Rate

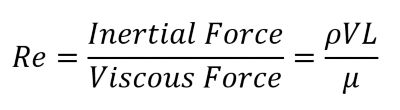

Non-dimensionalization is used in several branches of science and engineering. It effectively reduces the number of variables and enables meaningful correlations of physical phenomena in scalable systems. One example is the Reynolds number (Re), which calculates the ratio of inertial force to viscous force in a flow. A low Reynolds number below a certain threshold is known to cause ordered smooth laminar flow without significant mixing.

The Reynolds number can be calculated using the following equation:

In which ρ is the fluid density, V characterizes velocity defining the flow, L is a characterizing length in the flow system, and μ is the fluid molecular viscosity.

Viscous forces in a laminar flow tend to be large relative to the inertial force. An increase in the Reynolds number causes the flow to transition from laminar to turbulent, and it is characterized by its unsteady, random, and chaotic attributes with a variety of eddy structures. The Reynolds number at which the flow transitions from laminar to turbulent is called the critical Reynolds number.

The transition Reynolds number is affected by several factors, such as smoothness of the flow surface and disturbance in the surroundings. Its value is not universal. For internal flows with a smooth surface, it has value of approximately 2,300, and for external flows around an obstacle, it can be as high as 20,000.

Reynolds Number Limitations

The definition and interpretation of the Reynolds number is sometimes ambiguous. Misunderstanding can arise in the precise definition of characterizing velocity and length scales. At times, the Reynolds number is interpreted as the ratio of flow convection over flow dissipation. Other times, it is interpreted as the ratio of an artificially defined turbulent viscosity over molecular viscosity.

Not withstanding these differences, the fundamental definition of the Reynolds number as a ratio of inertial over diffusive effects is universally valid, and is a fundamental building block of computational fluid dynamics (CFD), with a wide range of applications.

Why is Reynolds Number Important for CFD Analysis?

CFD today is an indispensible tool in the design cycle of several industrial products.

The Reynolds number plays an important role in understanding the flow behavior of different design variants and operating conditions. An a priori knowledge of Reynolds number magnitude helps in the appropriate selection of physical models in a CFD study.

Contrary to common perception, CFD uses correlations representing physical laws and behavior in turbulence, heat transfer, multiphase, and combustion sciences. Many correlations directly depend on Reynolds number. Two examples include the Schille-Naumann drag correlation of a spherical droplet and the Ranz and Marshall heat transfer correlation in multiphase flows.

Reynolds numbers also help in the interpretation of a CFD solution. Turbulent and laminar flows show different characteristics affecting flow separation, stagnation behavior, and drag and pressure drop attributes. Knowledge of the global Reynolds number is useful in analyzing the different flow features and behavior.

The Reynolds number finds applications in fluid mechanics, such as in the calculation of friction factor and drag in internal and external flows. It lends value to hydraulics study, aero foil design, wind tunnel testing, and climate science.

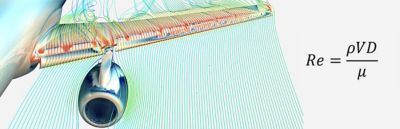

For example, engineers might ask, “How do we design an aircraft to be fuel efficient?” To answer these questions, engineers need to understand the fluid mechanics of airflow around an object. This is where CFD comes in. Engineers need to know the Reynolds number to accurately simulate the fluid flow.

当你有一个非常高雷诺数,your turbulence is intense, and that can cause a remarkably high amount of drag. You can use the Reynolds number to predict the transition from laminar to turbulent flow and model different situations to solve for drag.

A related example involves chemical engineering applications dealing with atomized fuels or droplets. These are modeled as correlations defined in terms of the Reynolds number. Atomized fuel droplets fly, burn, vaporize, and give power to an aircraft. Engineers must know the drag of the droplets to see whether they're going to vaporize or not and how far they will move in the combustor, in the gas turbine combustor, and the on the aircraft.

Reynolds numbers are also used in HVAC (heating, ventilation, and air conditioning). The engineering goal for HVAC is to minimize energy use while providing acceptable indoor air quality. To do this, engineers need to understand how airflow behaves as it moves through ducts, around furniture, and other objects in a room. The Reynolds number is a critical parameter in understanding this airflow.

In summary, the Reynolds number is essential for CFD because it is a fundamental building block used to predict the transition from laminar to turbulent flow, model different flow situations, and understand how airflow behaves.

Shorten Development Time with Ansys

引擎ersuse Ansys CFD softwarein a wide range of industries to simulate fluid flow and heat transfer in complex geometries. From concept design and optimization to final-stage testing, Ansys CFD solutions provide streamlined workflows, advanced physics modeling capabilities, and accurate results that can be trusted to make design decisions.

Learn more aboutAnsys Fluent, the industry-leading fluid simulation software known for its advanced physics modeling capabilities and accuracy.

ConsiderAnsys CFX, the industry-leading CFD software for turbomachinery applications, which provides an accurate and efficient way to simulate the complex flow physics of turbomachinery such as compressors, turbines, and pumps.