ANSYS BLOG

September 22, 2021

Solver-Based Meshing: How to Maintain a High-Quality Mesh

InHow to Mesh and Simulate Welds with Ansys Mechanicalwe discussed the need for a good quality mesh and strategies to generate meshes and welded connections, building on our earlierintroduction to FEA meshing. These meshes are essential for accurate solutions and enable you to make sound engineering decisions. In an analysis where geometric distortion (change of initial shape) is minimal, controlling the quality and size of the initial mesh is sufficient.

When the geometry is expected to have significant distortion, it’s hard to maintain the quality of the mesh as it deforms and distorts like clay in a child’s hands. In these situations, it’s useful to remesh to avoid distorted meshes. This can be cumbersome, especially if the remeshing step is done automatically without user intervention. Fortunately,Ansys Mechanicalcan remesh distorted elements in 2D and 3D analysis. Let’s discuss the two applications where solver meshing techniques are critical to solve complex problems.

Geometries can easily deform and distort like children playing with clay.

What is Nonlinear Mesh Adaptivity?

Simulation of manufacturing methods like rolling, drawing, and stamping are often accompanied by substantial shape change. Analysis of rubber seals or softened ductile metals to prevent fluid or gas leakage also cause severe distortion. In these types of analyses, the shape change is so severe that the quality of the initial mesh is lost.

Nonlinear mesh adaptivity(NLAD) resolves mesh distortion issues in such analyses. The solver keeps track of the mesh quality, and when distortion is seen, a higher quality mesh is generated. You have the flexibility to remesh the distorted region by refining, maintaining the same size, or coarsening the mesh.

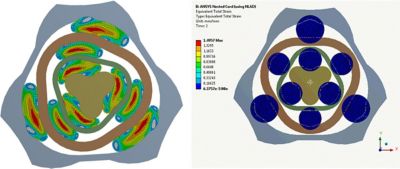

el NLAD解决方案astomeric cords crimped between multiple enclosures.

Advantages of Nonlinear Mesh Adaptivity

The technique can remesh when there is self-contact. This is typical when simulating rubber seals being squeezed into small crevices to prevent fluid or gas leaks in high pressure vessels, pipes, and other mechanical equipment.

An advantage of NLAD is controlling mesh discretization errors. When engineers design components, a nagging issue on the analyst’s mind is the accuracy of the results. A common error with coarse meshes in regions of interest leading to underpredicting the stresses at critical locations. Nonlinear mesh adaptivity can alleviate these issues by monitoring the ability of a mesh to capture variations in stresses and strains and refine them to better capture stress and strain changes in neighboring elements. For very large models such as engine blocks or in complex assemblies where the location of hot spot stresses remain unknown, having the solver automatically refine the meshes in selective regions to improve accuracy of results is a very powerful benefit.

A forging solution with the Ansys name using NLAD

Simulating Crack Growth with Adaptive Remeshing

再啮合技术也用于骨折growth simulation. Fatigue crack growth is a common failure in industrial equipment, aerostructures, and transportation frames, leading to loss of life and property. Predicting crack growth is critical to ensure safety. When cracks are in complex geometrical locations traditional handbooks fail. Separating, Morphing, Adaptive, Remeshing Technology (S.M.A.R.T) enables you to accurately predict crack growth under complex fatigue loading cycles. A principal challenge is the ability not only to predict crack growth and direction, but also automatically handle topology changes in the mesh and remesh the geometry with new crack faces in an automated manner.

S.M.A.R.T has matured to handle complex geometries like blades in gas turbine engines, engine blocks, and weld seams. The remeshing technology automatically creates new crack faces, refines the mesh at the crack-front, and coarsens the mesh in other regions to maintain accuracy while maintaining minimum mesh count.

Both NLAD and S.M.A.R.T are useful solver-based remeshing techniques. The automated remeshing capability shifts the burden of remeshing a new topology from you to the solver. Simulation processes that were cumbersome, time consuming, and error prone are now user friendly. This enables casual users and simulation specialists to solve complex engineering problems that were previously troublesome.

Crack propagation shown on a turbocharger geometry

Learn more by viewing the webinarAnsys Multiphysics Simulation for Crack Propagation Analysis, or take the courseAnsys Mechanical Fracture Mechanics.

查看 Ansys 的服務與產品

查看 Ansys 的服務與產品

立即聯絡我們

感謝您聯絡我們!

We’re here to answer your questions and look forward to speaking with you. A member of our Ansys sales team will contact you shortly.